Integral Fast Reactor

The Integral Fast Reactor (IFR) is Argonne Lab's best design,[1] a metal-fueled, sodium-cooled, pool-type [2] Fast Neutron Reactor, addressing all the issues raised in Nuclear_power_reconsidered (safety, waste management, weapons proliferation, and cost). "Integral" refers to the on-site reprocessing of the spent fuel.

Choice of Fuel and Coolant

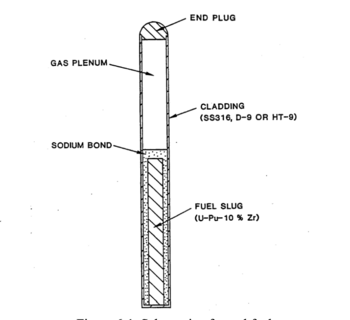

The IFR has a unique design for its fuel rods, which allows larger burnup of the fuel, and provides inherent safety if the rod ever gets too hot. The fuel slug is loose in the cladding, and there is space above the fuel to contain gaseous fission products released as the fuel is consumed. See Figure 1. In standard fuel rods, the cladding must be tight around the ceramic fuel pellets to ensure adequate thermal conductivity and avoid overheating the fuel. This limits the lifetime of the rods, because the fuel swells and the cladding cracks as the gaseous fission products accumulate. The loose fit in the IFR rods is possible, because the gap is filled with highly conductive liquid sodium. Pure metallic fuel can be used, instead of oxides, because the sodium doesn't corrode the fuel or the steel cladding. If the metal fuel gets too hot, it melts and expands into the gas plenum, shutting down the fission reaction.

Safety

The safety of the IFR design is ensured by several features:

1) The metal fuel, a low melting point alloy of U-Pu-Zr, will melt if the rod ever gets too hot. The fuel then expands upward in the steel cladding, shutting down the fission reactions (see Figure 1). The IFR is "walk away safe".

2) Many of the fission products bind chemically with sodium, reducing the risk of fission product release if there is fuel failure.

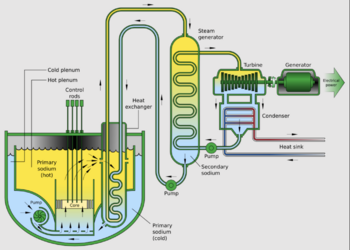

3) Convection in the large pool of molten sodium will easily handle the decay heat after a shut-down (see Figure 2).

4) The reactor vessel has no penetrations below the top of the pool, eliminating the possibility of sodium leakage.

5) There is no high pressure or any water near the reactor vessel.

6) The entire reactor chamber can be flooded with Argon, eliminating the possibility of a sodium fire.

Full-scale reactor tests were conducted at Argonne National Laboratory (West) in Idaho (now Idaho National Laboratory), in which the primary coolant pump was stopped with the reactor running at full power. All safety systems were disabled, and the control rods were held fully withdrawn. These "unprotected loss-of-flow tests" simulate the

extreme scenario where all safety systems and operator actions have failed.

The reactor shuts itself down with no damage and no radioactive leakage.[4]

Waste Management

Fuel rods have an advantage over molten salt fuels in that the fission products are contained in the rod. This means a smaller volume of radioactive spent fuel. Also rods are easy to identify and count, which may be advantageous in preventing diversion. A typical 500 MWe MSR produces 13 tonnes of Spent Nuclear Fuel (SNF) per year. A 500 MWe PWR produces ___ kg per year of SNF. A 500 MWe IFR produces ___ kg per year of (High Level Waste) HLW. Note: SNF can be reprocessed, and the final amount of HLW will depend on the details of that process.

Weapons Proliferation

The chemistry of the IFR fuel process does not allow extraction of weapons-grade material at any point in the cycle. Spent fuel is a mix of uranium, plutonium, and various actinides. Processing would be necessary by some other unrelated process, a situation not different in kind from starting with unprocessed fuel. So the IFR adds little or nothing to proliferation risk.[5] In countries not licensed for fuel processing, return of the spent fuel to a secure location could be handled as any other reactor with solid fuel rods. Rods are easy to count, and the number in transit at any one time can be small enough to avoid theft of a large quantity.

Cost

- No enormous pressure vessel with 6-inch steel walls.

- No huge containment building with 6-foot think, steel reinforced concrete walls.

Notes and References

- ↑ PLENTIFUL ENERGY The Story of the Integral Fast Reactor, Charles Till and Yoon Il Chang, 2011.

- ↑ The alternative "loop-type" is necessary in standard Pressurized Water Reactors. A low pressure coolant allows a larger "pool-type" reactor vessel capable of absorbing all the heat in an emergency shutdown. See Till & Chang, Section 5.4 The Reactor Configuration Choice.

- ↑ Schematic of the metal fuel rod. Fig.6.1 in Till & Chang, Chapter 6 IFR Fuel Characteristics.

- ↑ Experimental Confirmations of Limited Damage in the Most Severe Accidents,Till & Chang, Section 7.10.

- ↑ Nonproliferation Aspects of the IFR, Till & Chang, Chapter 12.