Integral Fast Reactor: Difference between revisions

(→Safety: add Fig.2) |

m (move Fig.2 to top) |

||

| Line 2: | Line 2: | ||

The '''Integral Fast Reactor''' is Argonne Lab's best design,<ref name=IFR/> a metal-fueled, sodium-cooled, pool-type [[Fast neutron reactor|Fast Neutron Reactor]], addressing all the issues raised in [[Nuclear_power_reconsidered]] (safety, waste management, weapons proliferation, and cost). "Integral" refers to the on-site reprocessing of the spent fuel. | The '''Integral Fast Reactor''' is Argonne Lab's best design,<ref name=IFR/> a metal-fueled, sodium-cooled, pool-type [[Fast neutron reactor|Fast Neutron Reactor]], addressing all the issues raised in [[Nuclear_power_reconsidered]] (safety, waste management, weapons proliferation, and cost). "Integral" refers to the on-site reprocessing of the spent fuel. | ||

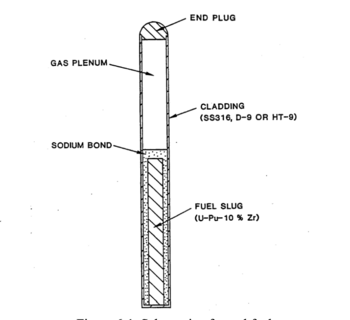

{{Image|Rod with Metal Fuel.png|right|350px|Fig.1 Fuel rod with high burnup and inherent safety.<ref name=IFR/>}} | {{Image|Rod with Metal Fuel.png|right|350px|Fig.1 Fuel rod with high burnup and inherent safety.<ref name=IFR/>}} | ||

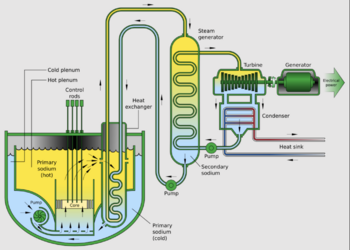

{{Image|Sodium-Cooled Fast Reactor.png|right|350px|Fig.2 Pool-type reactors have enormous heat capacity, and molten sodium will expand when hot, allowing convection to cool the core if the pump ever fails.}} | |||

== Choice of Fuel and Coolant == | == Choice of Fuel and Coolant == | ||

The IFR has a unique design for its fuel rods, which allows larger burnup of the fuel, and provides inherent safety if the rod ever gets too hot. The fuel slug is loose in the cladding, and there is space above the fuel to contain gaseous fission products released as the fuel is consumed. See Figure 1. In standard fuel rods, the cladding must be tight around the ceramic fuel pellets to ensure adequate thermal conductivity and avoid overheating the fuel. This limits the lifetime of the rods, because the fuel swells and the cladding cracks as the gaseous fission products accumulate. | The IFR has a unique design for its fuel rods, which allows larger burnup of the fuel, and provides inherent safety if the rod ever gets too hot. The fuel slug is loose in the cladding, and there is space above the fuel to contain gaseous fission products released as the fuel is consumed. See Figure 1. In standard fuel rods, the cladding must be tight around the ceramic fuel pellets to ensure adequate thermal conductivity and avoid overheating the fuel. This limits the lifetime of the rods, because the fuel swells and the cladding cracks as the gaseous fission products accumulate. | ||

| Line 7: | Line 9: | ||

== Safety == | == Safety == | ||

== Waste Management == | == Waste Management == | ||

Revision as of 13:59, 21 March 2023

The Integral Fast Reactor is Argonne Lab's best design,[1] a metal-fueled, sodium-cooled, pool-type Fast Neutron Reactor, addressing all the issues raised in Nuclear_power_reconsidered (safety, waste management, weapons proliferation, and cost). "Integral" refers to the on-site reprocessing of the spent fuel.

Choice of Fuel and Coolant

The IFR has a unique design for its fuel rods, which allows larger burnup of the fuel, and provides inherent safety if the rod ever gets too hot. The fuel slug is loose in the cladding, and there is space above the fuel to contain gaseous fission products released as the fuel is consumed. See Figure 1. In standard fuel rods, the cladding must be tight around the ceramic fuel pellets to ensure adequate thermal conductivity and avoid overheating the fuel. This limits the lifetime of the rods, because the fuel swells and the cladding cracks as the gaseous fission products accumulate. The loose fit in the IFR rods is possible, because the gap is filled with highly conductive liquid sodium. Pure metallic fuel can be used, instead of oxides, because the sodium doesn't corrode the fuel or the cladding. If the metal fuel gets too hot, it melts and expands into the gas plenum, shutting down the fission reaction.

Safety

Waste Management

Fuel rods have an advantage over molten salt fuels in that the fission products are contained in the rod. A typical 500 MWe MSR produces 13 tonnes of Spent Nuclear Fuel (SNF) per year. A 500 MWe PWR produces ___ kg per year of SNF. A 500 MWe IFR produces ___ kg per year of (High Level Waste) HLW. Note: SNF can be reprocessed, and the final amount of HLW will depend on the details of that process.

Weapons Proliferation

Cost

Notes and References

- ↑ 1.0 1.1 Fig.6.1 in PLENTIFUL ENERGY The Story of the Integral Fast Reactor, CHARLES E. TILL and YOON IL CHANG, 2011.